How 3 Mil Bag Thickness Can Enhance Your Business

Mil Bag Thickness

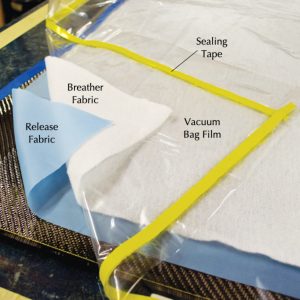

Vacuum bag molding is the principal composite production technique for creating laminated structural objects. This is very popular in the aerospace sector. The most common components in this process include fiberglass plates, nylon mesh, and other materials that are rolled into shapes. In order to create a quality product, high-quality vacuum bags are required. It is necessary to make use of a vacuum pump while performing this process.

There are several advantages of using vacuum bags. The first is their ability to provide the users with a strong and durable structure. It is very common to find industries that have a wide range of vacuum sealer bags that can be used for numerous purposes. In addition to their strength, they can also be used in large amounts because of the multiple sizes that they come in.

There are several types of vacuum bags. There are two types of bag construction which include the notched vacuum bags and flat vacuum bags. Both these types come with an advantage, which is their durability. For one thing, they are extremely resistant to punctures. You can expect them to remain intact until the time that you decide to discard it. Another benefit that you can get from these notched vacuum bags is that you do not need to purchase a large number of them in order to provide the customers with a high-quality product.

How 3 Mil Bag Thickness Can Enhance Your Business

When you use flat vacuum bags, it is very easy for you to create channels. It is because they have different thicknesses. The flat type of vacuum bags has a thickness of three mil thickness, while the notched variety has a thickness of between two to four mil thickness. It is important to note that the flat type of this product offers a very large surface area compared to the other option.

In addition, when you compare the benefits provided by the notched and flat type of vacuum bags, it is quite obvious that you will achieve better results with the former. This is because you can produce more bags with greater ease. On the other hand, the flat type of vacuum bag has smaller surface areas. Because of this, you can expect to achieve a higher production rate from your product.

These are some of the benefits you can obtain when you make use of three mil bag thickness, which is an excellent option when you are looking for custom vacuum bags. This is especially so if you are someone who has a low-income and cannot afford to invest a huge amount of money on a new inventory of vacuum bags. However, you should know that investing in such an item may be beneficial in the future. For one thing, you will be able to improve your sales because you will be able to offer your customers better quality products for a reasonable price.